Companies talk > Interview with T.M.E. S.r.l.

Interview with T.M.E. S.r.l.

- Company year of incorporation: 1995

- Year of association to the Consortium: 1999

- Turnover class: 4 mln €

- Products: Fluid Ends for Mud Pumps, Oil&Gas parts and components (tees, crosses, adapter spools, spacer spools, flanged connectors, drill stem subs etc)

- Industries: Oil & Gas and Energy production

- Foreign markets: mainly Extra EU, MENA, North and South America.

We thank Eng. Gandini, Production Manager of Tecno Meccanica Emiliana S.r.l. for participating in our interview:

Good morning ing. Gandini, can you describe the growth path of the T.M.E. on international markets?

Tecno Meccanica Emiliana has always turned to foreign markets since its foundation on 27 October 1995 and since then has been dealing with Drilling, in particular for Oil & Gas. Although at the time our main customers were on the national territory, our production was all destined for abroad. The company has specialized in the production of components for Mud Pumps, more precisely Fluid Ends and for years has maintained itself as a supplier to large companies in Italy.

Can you tell us more about the company and its products?

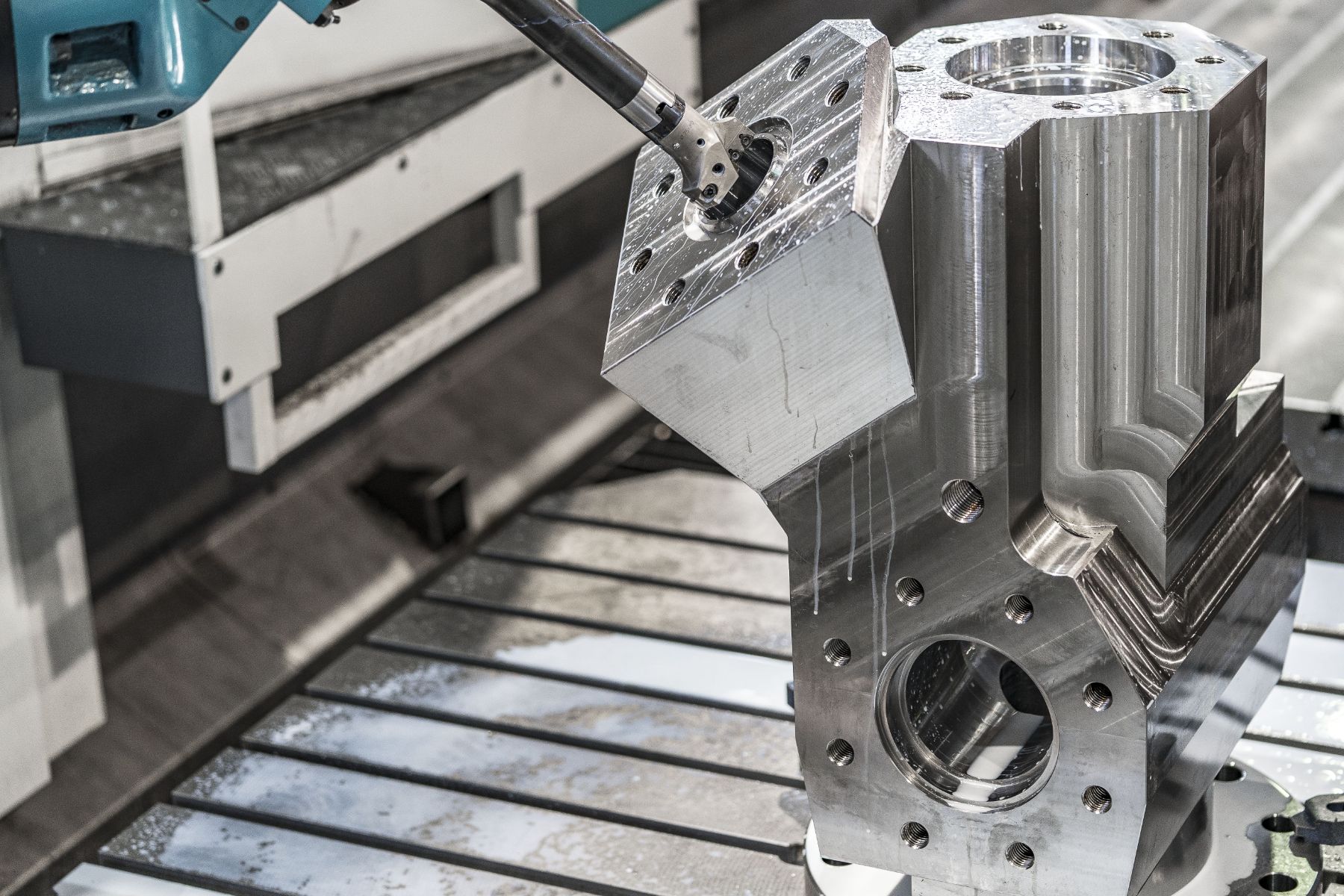

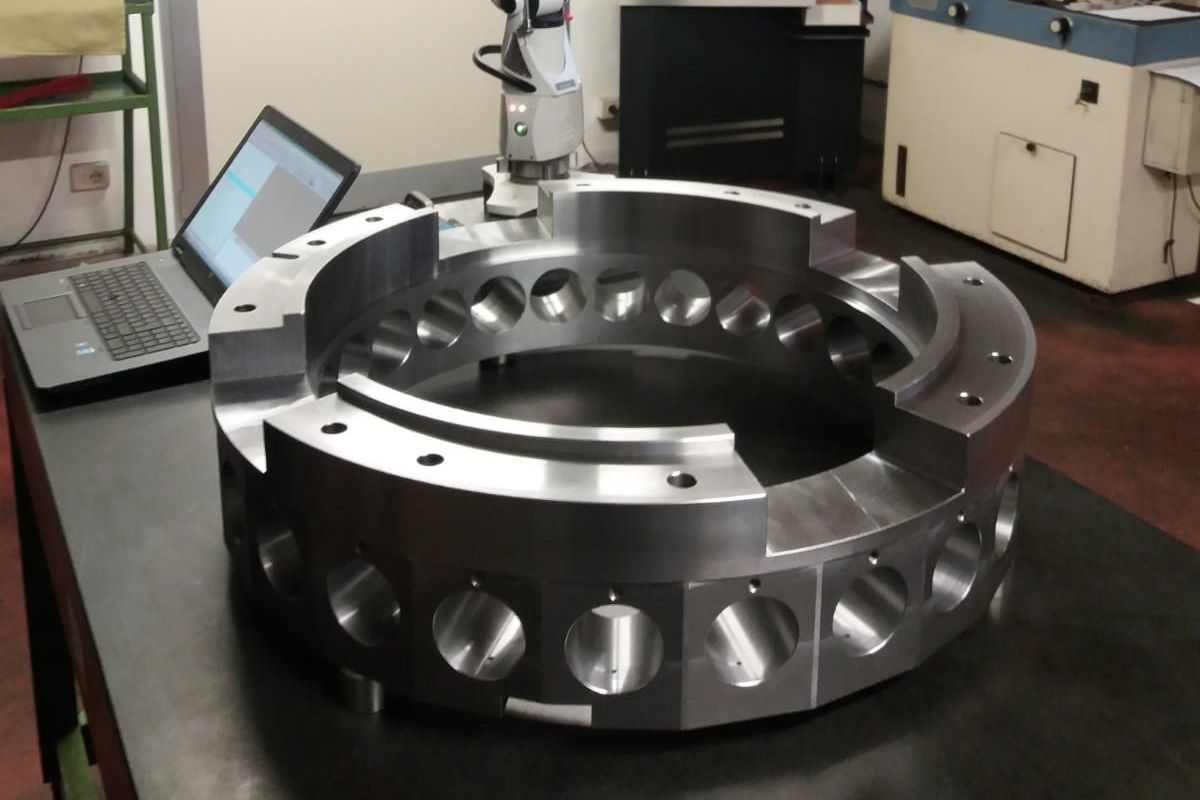

As I mentioned before, Tecno Meccanica Emiliana S.r.l. had the will to create since the beginning a company structure divided into three different activities that are strictly complementary to each other (study / design, mechanical carpentry, machining with CNC and traditional machine tools). This structure has the aim of offering customers a single interlocutor for a range of services as complete as possible, also, and above all, in relation to the supply of numerically reduced batches or even of the single piece and prototypes.

The study / design activity is carried out by the technical office located in Piacenza, while metal working and mechanical processing are located in two separate factories, each having an area intended for the production of approx. 1.200 and sqm. 2,000, and both located in the Ponte Trebbia industrial area of Calendasco (PC). Since March 2003 the company has been certified according to the ISO 9001 standard and, starting from July 2013, it has obtained the certifications in accordance with API 6A - API 7-1 - API 7K - API 8C and API Q1.

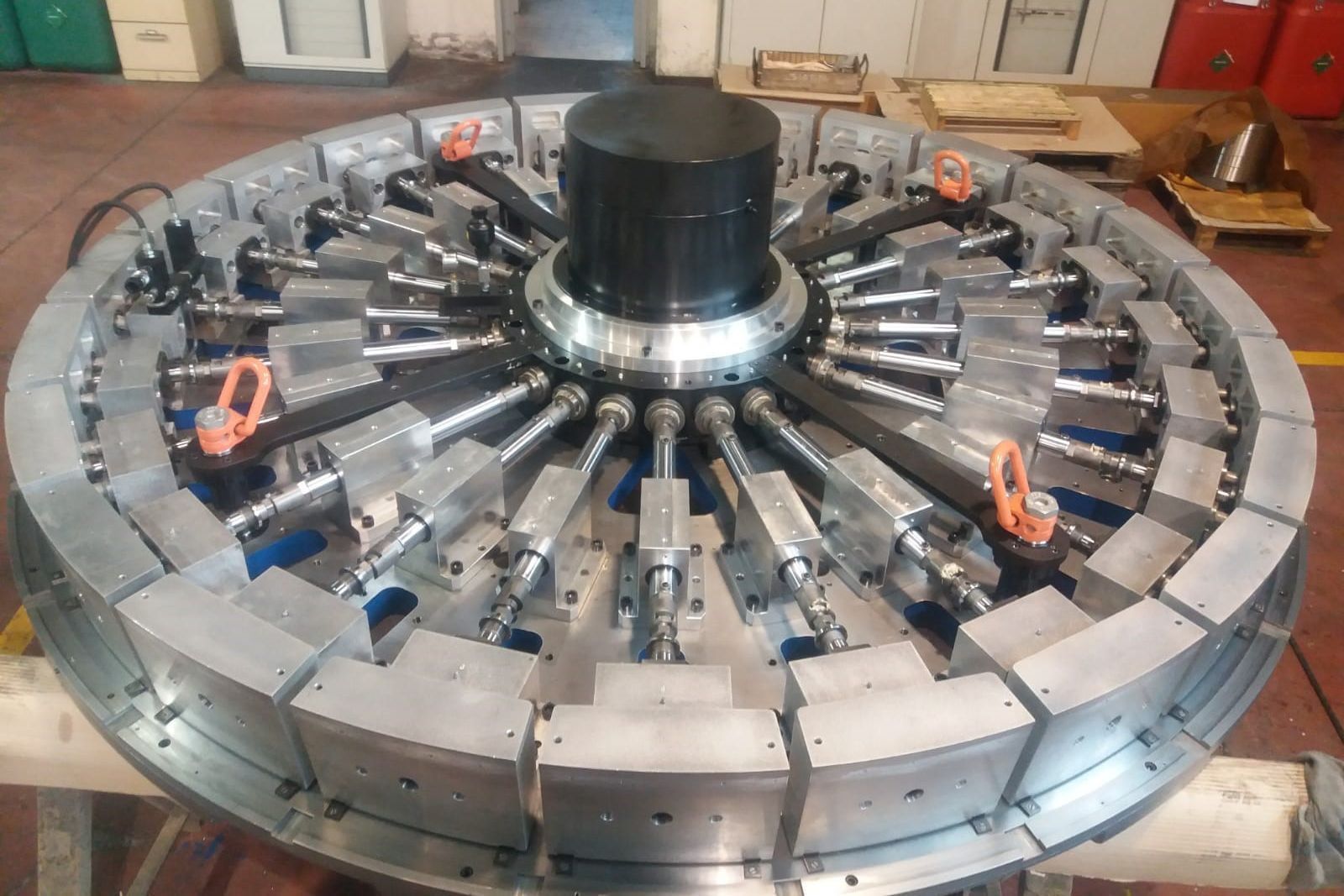

These certifications have allowed us to expand over time on foreign markets and to propose ourselves directly, in particular to large companies that deal with Drilling in the Oil & Gas sector. Tecno Meccanica Emiliana manufactures, in addition to the Fluid End Groups, various other components that are used in drilling and extraction systems for oil and gas (tees, crosses, adapter spools, spacer spools, flanged connectors, drill stem subs, toothed wheels, gears, crowns, pinions, multi-groove pulleys, drive head cases, liners, pistons, etc ...); moreover, at its own technical office, there is the possibility to design and build parts for special applications on customer request.

Can you tell us about your relationship with CEPI?

Since the beginning we have had great support from CEPI for what concerned all the documentation for the management of shipments and orders from abroad, even starting from basic information such as the type of pallets, or the contracts necessary to start a relationship with our foreign partners or customers directly.

The experience of the Consortium was also useful during the negotiation phases for the modification or insertion of contractual elements of purely commercial value, such as the conditions of exclusivity or confidentiality that must be managed correctly in order not to have nasty surprises later.

CEPI's support was also invaluable throughout the opening phase of the partnership in Saudi Arabia (which involved the opening of a technical-operational support structure on site) and for what concerned the issues relating to different taxation that we encountered in various countries such as Egypt and Saudi Arabia.

We also make use of the support of the Consortium for all TME trade fair participations: in Texas, in the United Arab Emirates, in Italy and in Russia, the CEPI was helpful in organizing the participation, finding the fundamental services, the linguistic ones and also the exhibition stands.

What are your current plans for the future?

The expansion towards the hydroelectric energy market certainly constitutes a differentiation line with respect to Oil & Gas. However, we can say without doubt that the crisis due to the Covid pandemic has not had a significant impact on our activities: drilling has not stopped as it is linked to production and sales cycles that are much longer than a single calendar year. Furthermore, where the new works had stopped, we continued to work to carry out all the repairs, replacements and maintenance necessary for the proper functioning of the systems.

It is also important to remember that from 2019 T.M.E. has purchased new machinery which in terms of equipment and specificity are almost unique in Italy. This will allow us to be able to internally manage orders for much larger products in terms of size and to significantly improve delivery times. As a result, we will be able to provide more specific and customized solutions to our customers more quickly and while maintaining absolute control over the quality standards required in all production processes.